Cobalt Chains will begin offering CNC Laser Profiling as of January, 2020. This new service will enhance our in-house machining capabilities by offering greater accuracy, more versatility, improved efficiency and cleaner, more consistent products. We are excited to implement laser profiling for our current products, including sprockets, flights and attachments, but furthermore to offer new products to meet your custom designs.

With our new 6,000 kW laser, we will be able to cut carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized steel and other materials at thicknesses up to one inch. Together with our sales and engineering teams, we will be able to cut almost any design you will need. We invite you to contact us today at 309-698-9250 or sales@cobaltchains.com for more information on this highly flexible service.

Laser Capabilities:

- 6,000 kW

- 120” x 60” working size

- Material up to 1” thick

- +-0.05 mm/m X/Y accuracy

- +-0.02 mm Repeat Positioning

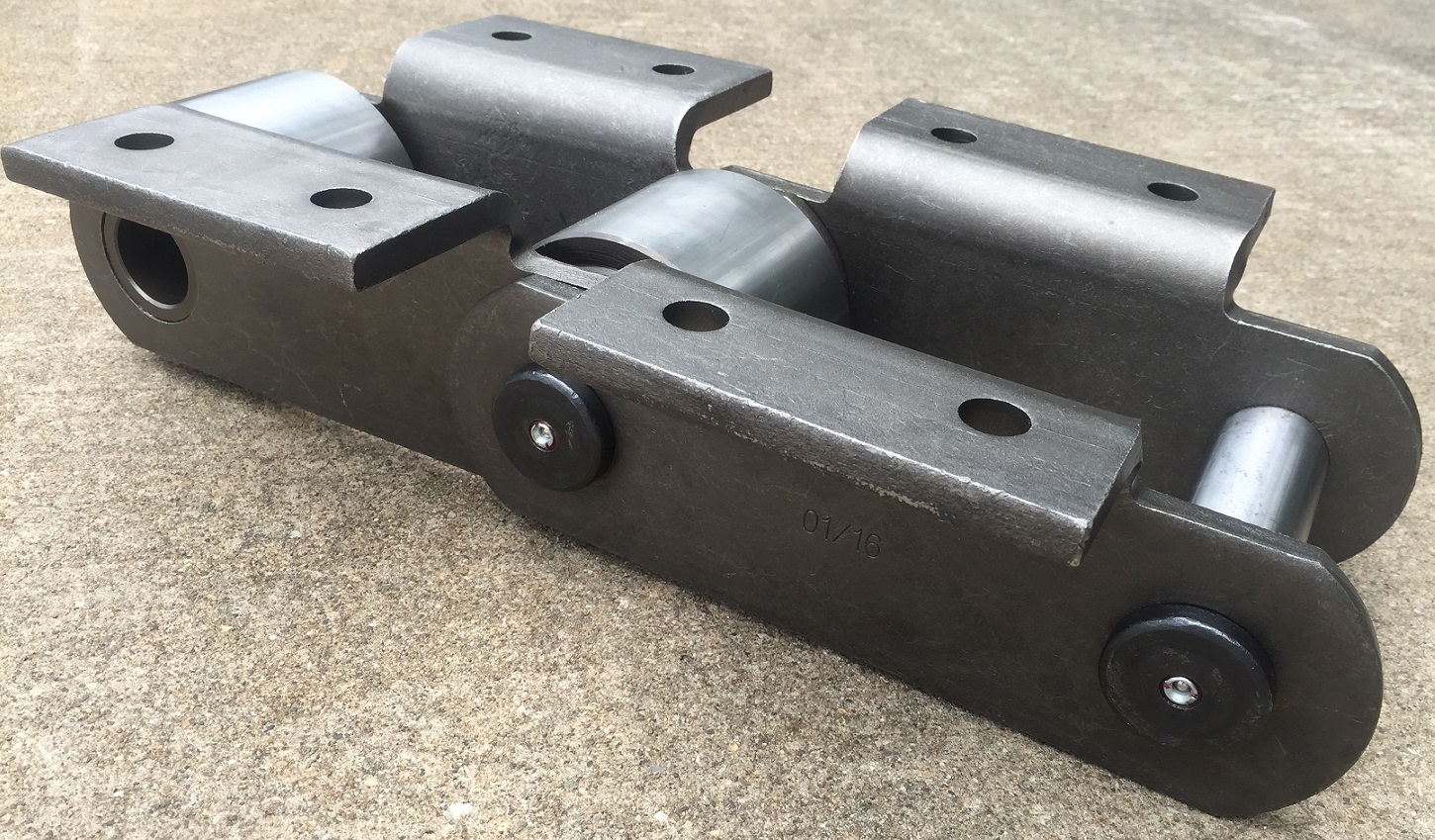

Since 2004, Cobalt Chains has been your source for industrial chains. Located in East Peoria, Illinois, the company has excelled through the constant development of new markets and new product lines to emerge as a worldwide supplier of premium conveyor and power transmission chains.

Serving the industries of agriculture, cement, construction, food processing, lumber, manufacturing, mining, plastics and chemical, power generation, pulp and paper, sugar, and steel, Cobalt offers in-house fabrication of chain, chain attachments, and sprockets to create custom solutions to meet almost any application. As an ISO 9001:2015 certified company, Cobalt Chains inspects and quality controls each chain, sprocket, and attachment, and is dedicated to its position as a world-leader in the conveying industry.