Established in 2004 by President and CEO Chris Robinson and Partner Jonathan King, Cobalt Chains, Inc. is your source for quality chains and components for the Sugar Industry. Combined, Chris and Jonathan have over 60 years of experience in the power transmission and conveying industries. Under their leadership, Cobalt Chains has become a proven supplier of industrial conveyor chains and sprockets in all the toughest of industries, such as Sugar, Cement, Agriculture, Mining, Pulp and Paper, Power Generation and more. Through continuous improvement, innovative thinking and time-honored values, Cobalt Chains delivers quality, reliability and superior performance, all at a competitive price, and our employees, partners and products are all aligned to exceed your expectations.

Centrally located in East Peoria, Illinois USA, Cobalt Chains has excelled through the constant development of new markets and product lines to emerge as a true worldwide leader in premium conveyor and power transmission products. In recent years, the company has gone through a rebranding – establishing the Cobalt Chains identity and allowing our products to be sold worldwide. Demonstrating the company’s commitment to providing the best possible services to our customers, we have recently completed construction of a new warehouse – expanding the company’s operating facility approximately 33%, increasing our stock capacity and allowing for the addition of a CNC laser to our in-house machining equipment.

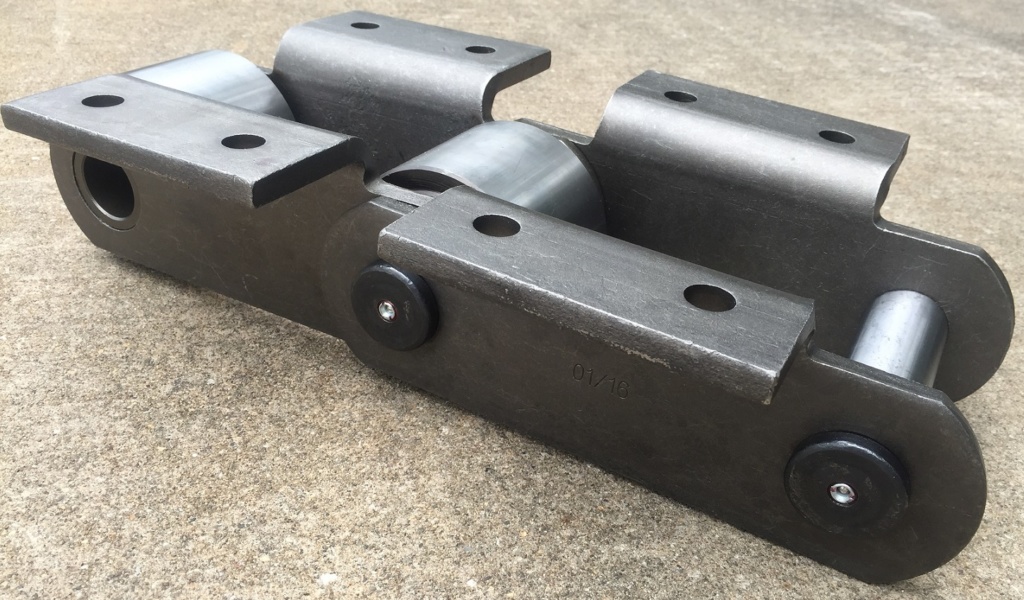

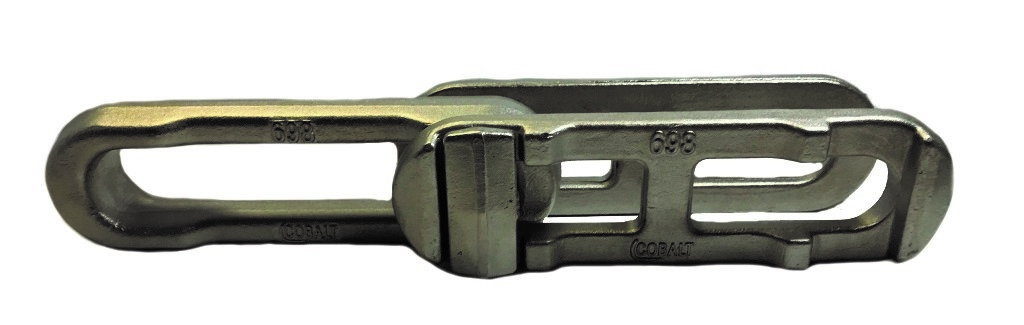

With years of service to sugar mills in the United States, and the widest selection of in-stock and made-to-order chains of any North American chain manufacturer, the Sugar Industry has become one of our flagship industries. We supply sugar mills with unique chains using special alloys designed specifically for each step of sugar production, including feeding, cane carrying, elevating, juice straining/cush cush elevating, and bagasse transporting. Some of the typical chains offered include welded steel chains with premium, heat treated sidebars and induction hardened pins for maximum strength and durability, drop forged rivetless chains with no rotating parts to avoid suffering from abrasion caused by dirt and sand brought into the mill with the cane, main cane & auxiliary carrier chains with standard and made-to-order attachments, offset link drive chains and roller chains. Furthermore, we provide several types of chains that are unique to the Sugar Industry – among them are Outboard Roller Cane Carrier Chains, Forged Intermediate Carrier Chains, Diffuser Chains, Cush Cush Elevator, Bagasse Conveyor & Elevator Chains, Bucket Elevator Chains, and Boiler Grate Chains. We can make any chain to your specified alloy steel, including martensitic stainless steels 420 and 440, and even special grades 17-4 PH and HK40. Additionally, we can offer special heat treatment to obtain necessary hardness characteristics.

Through annual sales to nine of the eleven sugar mills in Louisiana, and a 60% market share in that region, Cobalt Chains has proven to be a dedicated Sugar Industry supplier. Our customers in the Sugar Industry choose Cobalt Chains because of the durability of our products – customers can be confident they have a quality chain that won’t let them down during production and they know that they can maximize their efficiency during this process. We are determined to offer the best quality product, at the lowest price, and the best customer service in the business – and our customers can rest easy knowing that all of this is backed up by a standard warranty on all physical goods – more information on this warranty can be found at our website – www.cobaltchains.com

Conveyor chains can help complete a number of different jobs in the sugar industry, but a conveyor system needs sprockets to run the chain, and we are here to help with these as well. With a full-service, in-house machine shop, we can fabricate any size sprocket to meet the demand. Sprockets are generally made-to-order and can be made to fit standard or multi-row chains, be bolt-on or weld-on A-Plate or be made with ‘B’ or ‘C’ style hubs to meet the customer’s need. Other common variations of sprockets used in the Sugar Industry include tapered-bushed, half-pitched, split and mud-groove.

While offering the largest selection of chains on-hand, Cobalt Chains is not limited to providing you just a stock chain and sprocket. We provide custom solutions to your specific conveying needs. To do this we make specially designed attachments for your chain. From slats and scrapers to elevator buckets, you tell us what you need, then our in-house machine shop will get to work fabricating it, and our warehouse staff will sub assemble chains in manageable lengths for a custom, turnkey solution.

Moreover, while our machining specialties are attachments, sprockets and shafts for the chains we manufacture, we are not limited to these products and are able to fabricate other machined parts as required. We have a fully equipped shop with CNC machinery including lathes, end mills, machining centers, presses, saws, hi-definition plasma, press brakes and a shear, and we are excited to announce the introduction of CNC Laser Cutting to our in-house services. With this new 6,000W Fiber Laser, we can offer greater accuracy, versatility and efficiency in metal cutting. This means a cleaner, more consistent product for the customer, in less time. It also gives us the flexibility to further tailor our products to meet your unique needs. With this laser we can cut any design in carbon steel and stainless-steel materials, up to 1” thick. Our in-house capabilities do not end with machining either, as we have full shop welding capabilities including MIG and TIG. In 2016, we went a step further and installed a CNC automated welding robot to assure the highest quality of the production welds we perform. This robot has enabled us to speed up delivery times and reduce pricing on welded flights. By combining our machining and welding capabilities, we can quote and supply almost any attachment for your conveying projects.

Throughout the ordering process, the Cobalt Chains Engineering team is here to help ensure that you end up with the right solution. Upon receipt of a new order, our Engineering department will create an AutoCAD drawing of your product so that you can review and be confident that you are getting exactly what you ordered – and what you need. This is part of our commitment to quality and to helping our customers achieve and exceed their goals. Our number one goal is to achieve 100% customer satisfaction, which is accomplished by providing the best products, on-time delivery and service consistency. Furthermore, our dedicated employees help to achieve this goal by their continued involvement and commitment from quote to delivery.

To ensure that all of this comes together as a consistent, quality product, we have adopted the ISO 9001 Quality system as a foundation to provide a work environment that will promote learning, team involvement and continuous improvement. We initially became ISO9001:2008 certified in 2015 and have since continued to improve our quality management system and have now obtained ISO 9001:2015 certification.

At Cobalt Chains, we are committed to our position as a world-leader in the conveying industry, and we look forward to continuing to grow our presence in the Sugar Industry around the globe. For more information about our company, products and services, please visit our website – www.cobaltchains.com or contact sales@cobaltchains.com to request a catalog or quote.