Cobalt Chains, Inc. broke ground in April on a construction project to expand to the company’s headquarters in East Peoria, Illinois.

Upon completion of construction, the size of Cobalt’s manufacturing factory will grow approximately 1/3 larger, allowing for the expansion of in-house fabrication capabilities and the installation of a second robotic welder. Coupled with a larger inventory capacity, this will allow the company to continue accelerating delivery times, while improving efficiency and cost effectiveness for customers. Chris Robinson, President of Cobalt Chains, is eager to have more room to work with, saying, “We continually strive to better serve our customers. By increasing the size of our facility, we will be able to do exactly that by keeping more products on-hand and offering quicker turn-around times.”

The larger building will not only enable Cobalt to better serve current customers, but will support continued growth into international markets. Robinson says, “Cobalt Chains has developed a solid North American market, but a larger shop will allow us to better serve clients here and anywhere in the world, while helping to secure the future of the company.”

Since 2004, Cobalt Chains has been your source for industrial chains. Centrally located in East Peoria, Illinois, the company has excelled through the constant development of new markets and product lines to emerge as a worldwide supplier of premium conveyor and power transmission chains.

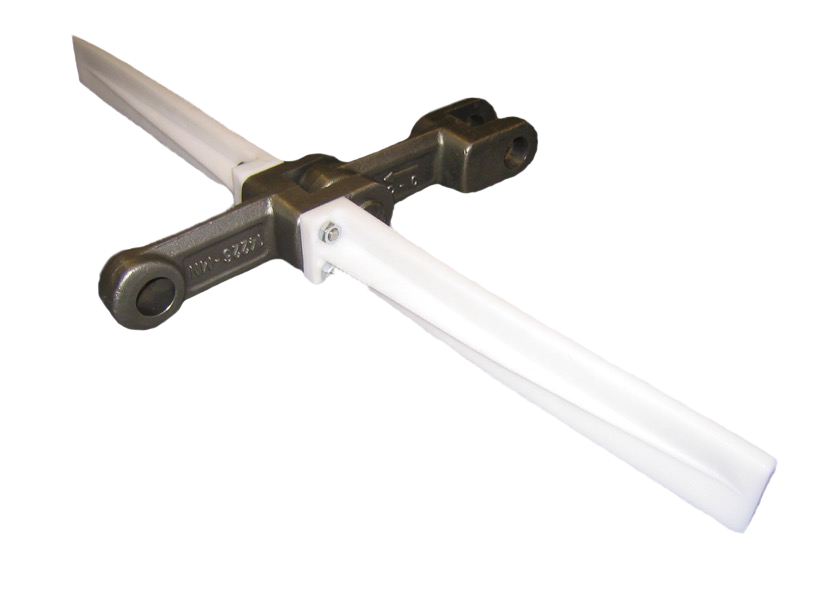

Serving the industries of agriculture, cement, construction, food processing, lumber, manufacturing, mining, plastics and chemical, power generation, pulp and paper, sugar, and steel, Cobalt offers in-house fabrication of chain, chain attachments, and sprockets to create custom solutions to meet almost any application. As an ISO 9001:2015 certified company, Cobalt Chains inspects and quality controls each chain, sprocket, and attachment, and is dedicated to its position as a world-leader in the conveying industry.